Hebei Crown Wealth is a professional manufacturer and supplier of electrical hardware. In our production of power hardware products, we have used various materials, such as stainless steel, nylon, ABS, galvanized steel, and more. Among these, stainless steel is our most commonly used material. The multiple alloy elements in stainless steel each have unique properties, making it an ideal solution for electrical hardware projects. Next, we will explore the 10 major benefits of stainless steel applications.

Table of Contents

ToggleBenefits of Stainless Steel

#1 Corrosion Resistance

One of the most famous benefits of stainless steel is its strong corrosion resistance. Why does stainless steel have outstanding corrosion resistance? This is because the chromium alloy element in stainless steel plays a crucial role. Chromium can form an inert layer of chromium oxide on the surface, acting as a protective barrier. This is most evident in 304 stainless steel and 316 stainless steel. 316 stainless steel also contains 3% molybdenum alloy, further enhancing its corrosion resistance in high-salt and industrial acidic or alkaline environments. So the corrosion resistance of stainless steel ensures that your hardware remains intact and functional over time, preventing rust and deterioration.

#2 Fire, High and Low-temperature Resistance

Stainless steel reduces the carbon content and increases the Cr and Ni content, ensuring high strength while maintaining excellent toughness. The Cr and Ni alloy elements resist scaling at high temperatures, maintaining the strength of stainless steel. The melting point of stainless steel is very high. Even the lower-cost 201 stainless steel has a melting point of 650 degrees Celsius, while the melting points of 304 stainless steel and 316 stainless steel are much higher than that of 201 stainless steel (the specific melting point depends on the alloy composition). If your project is in an environment exposed to wind, snow, rain, or coastal climates, you can rest assured that Cr and Ni will exhibit their properties, ensuring the stability of the stainless steel material. In fire-resistant, high-temperature, and low-temperature environments, stainless steel outperforms galvanized steel and aluminum, making it an ideal solution for your project applications.

#3 Strength-to-Weight Advantage

The alloy elements contained in stainless steel, such as C, Cr, and Ni, ensure the material’s toughness, durability, and high strength. 201, 304, and 316 stainless steels are all austenitic stainless steels that can maintain their high strength even under cold working conditions. Compared to carbon steel, stainless steel can be used to create robust structures or components while also reducing some weight.

#4 Impact Resistance

Stainless steel is alloy steel with a carbon content not exceeding 1.2%. Low-carbon steel possesses good toughness. Therefore, the excellent impact resistance ensures that stainless steel components in your project maintain their structural integrity and performance when subjected to sudden forces or impact loads.

#5 Ease of Fabrication

Stainless steel shows excellent machinability and operability in manufacturing such as cutting, welding, bending and forming. Its chemical composition and mechanical properties remain consistent throughout production, ensuring the stability and reliability of the finished products. This makes stainless steel the preferred material for manufacturing products and structures in the power hardware industry and many other sectors.

#6 Wide Range of Applications

Stainless steel’s exceptional corrosion resistance, high-temperature tolerance, superior strength, and versatility make it an ideal material for numerous applications. It is commonly found in power and telecommunication hardware, construction, chemical and pharmaceutical industries, new energy, industrial equipment, and household products. Some artists even sculpt stainless steel into beautiful works of art.

#7 Hygienic Properties

Stainless steel is a very hygienic material. Don’t be surprised, because the smooth, glossy surface of stainless steel does not allow dust, dirt, and bacteria to take root, making it very easy to clean or disinfect. Even if contaminants do adhere, they are easily removed. This is why stainless steel is a common material in kitchens, medical instruments, laboratories, and precision equipment facilities.

#8 Aesthetic Appearance

Stainless steel has been seen as an elegant and attractive material since it was discovered by Harry Brearly in 1913. After surface treatments such as brushing, polishing, and satin finishing, stainless steel becomes even more glossy, making it an ideal choice for both functional and decorative purposes. Moreover, this beautiful surface can withstand the test of time.

#9 Long-Term Value

When considering the total lifecycle cost, stainless steel is often the ideal solution for your project applications. Stainless steel materials typically incur almost no maintenance costs throughout their entire lifecycle. Compared to carbon steel, stainless steel is an extremely durable metal that can withstand daily wear and corrosion, resulting in a longer service life. From a long-term value perspective, choosing stainless steel will also provide you with a substantial return on investment.

#10 100% Recyclable

According to relevant statistics, over 50% of new stainless steel is made from discarded stainless steel that has been remelted, with no change in structural performance. Recycling discarded stainless steel reduces the demand for newly mined raw materials, which in turn helps protect the natural environment.

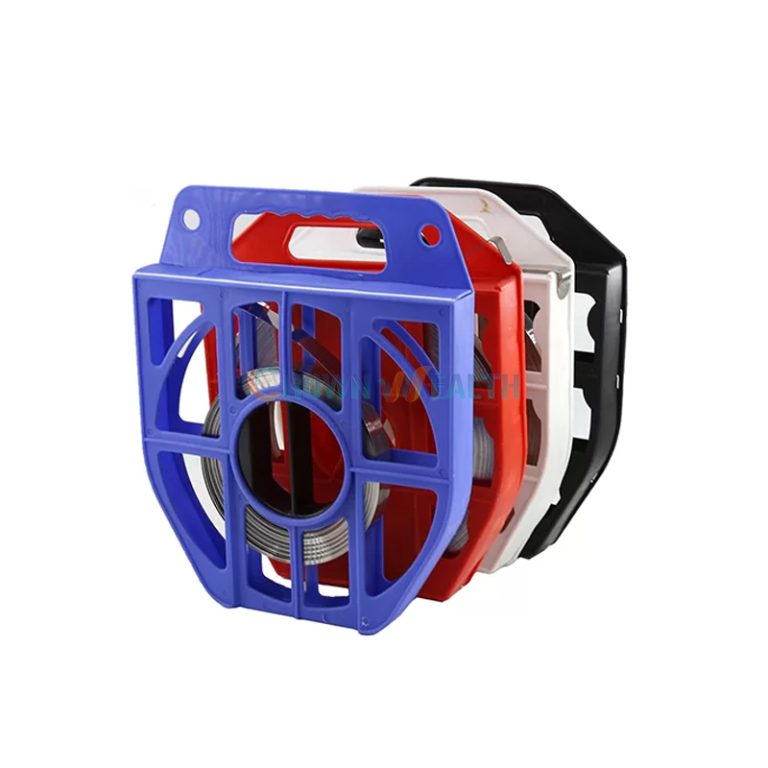

What Accessories do Electrical Manufacturers Use Stainless Steel for?

Electrical manufacturers primarily choose stainless steel for producing electrical hardware due to its outstanding properties, including corrosion resistance, high strength, and durability. Hebei Crown Wealth Metal Products Co., Ltd. is a professional manufacturer and supplier of electrical hardwares. Our uses stainless steel materials to make stainless steel products including Pole Line Hardware, Aerial Drop Hardware, Stainless Steel Banding, Stainless Steel Buckle, Banding Bracket, Banding Tool, Stainless Steel Cable Ties, Cable Clamps, FTTH Accessories, Fiber Optic ODF, and Network Rack etc.

Conclusion

Stainless steel is used in various utility pole hardware facilities in harsh environments (such as humid, acidic, and alkaline indoor and outdoor conditions) due to its resistance to surface corrosion, pitting, rust, and wear. It offers corrosion resistance, high strength, durability against deformation, and environmental benefits. Our high-quality stainless steel hardware products have been exported to over 60 countries and regions. Since 2011, we have established long-term, stable partnerships with well-known distributors in the United States. Our consistently high-quality stainless steel products and comprehensive services have been well received by our customers. Our company always adheres to the principle of “quality first, customer foremost,” striving to be an excellent enterprise and to produce first-class products. Please feel free to contact us.

FAQ

What is Stainless Steel?

Stainless steel is an alloy metal known for its resistance to rust and corrosion. The main alloying elements include iron, chromium, nickel, and other elements such as molybdenum, carbon, silicon, and manganese. The proportion of these elements in stainless steel depends on its intended use and cost. The corrosion resistance of stainless steel comes from the inclusion of at least 10.5% chromium. This element forms an inert layer of chromium oxide on the surface, serving as a protective barrier. Additionally, stainless steel has a low carbon content, which gives it good toughness.

How is Stainless Steel Made?

Different grades of stainless steel may undergo varying processing methods. Forming, machining, and finishing greatly influence the appearance and performance of stainless steel. Here’s a brief overview of the manufacturing process for most stainless steels:

- Melting and Forming

- Decarburization and Casting

- Hot Rolling, Cold Rolling, Annealing, Descaling, or Pickling

- Cutting and Finishing

- Quality Control

- Packaging and Distribution

What are the Grades of Stainless Steel?

Common main grades of stainless steel:

- Austenitic Stainless Steel: Known for its excellent corrosion resistance, formability, and weldability. Common grades include 201, 304, and 316 stainless steels. Hebei Crown Wealth’s hardware products are primarily made from austenitic stainless steel.

- Ferritic Stainless Steel: Contains low nickel content and is magnetic. Examples include 409 and 430 stainless steels. These are generally less expensive than austenitic stainless steels.

- Martensitic Stainless Steel: Has higher carbon content, providing excellent strength and hardness. Common grades are 410 and 420 stainless steels, often used in cutlery, valves, and pumps.

Does Stainless Steel Rust?

Stainless steel contains at least 10.5% Cr, Which forms a thin layer of Cr oxide on the surface when exposed to oxygen. This passivated protective layer can effectively prevent stainless steel from oxidation and corrosion. For environments with high exposure to salt or chemicals, use grades like 316 or duplex stainless steels. The corrosion resistance and durability of 304 stainless steel in a general atmospheric environment are sufficient to meet your needs, but if your project cost is limited, it is recommended to choose 201 stainless steel, which will not rust in a short time.