◇ Safe to use, versatile and reliable;

◇ No stripping required, fully insulated;

◇ No contact at any point with a live part;

◇ Standard: NFC 33 020, ANSI C119.4 and EN 50483-4

The insulation piercing clamps are made of UV-resistant thermoplastic fiber and reinforced with tinned copper for extra strength and protection. Depending on your specific application area, we can provide you with puncture clamps and components that vary in different sizes.

Insulation Piercing Connector an insulated connector used to connect protected overhead line cables (with neutral), transformer downspout or service drop cables.

It is suitable for different combinations of aluminum and copper,main and branch conductor.The universal piercing connector shall primarily be used as an insulated tap off clamp.

All our insulation piercing connectors are designed and rigorously tested to fit most international standard cable types, whether your cables are insulated with XLPE, PE or PVC.

Warm Tips: These connectors are used to establish connections between bare aluminum cable and insulated aluminum cable. And live-line work or power-cut work is allowable.

Hbcrownwealth is a specialist in overhead line hardware manufacturer. We have more than 10 years of manufacturing and exporting experience, and we have a very precise control over products and raw materials. We can produce products you that meet the quality requirements of your local market and save you costs. Contact us now to allow us to provide you with free samples and the best Ex-factory insulation piercing connector price.

» Read More

No terminal box and splice closures required.

Low contact resistance and low temperature rise of wire clamps.

The structure is sealed and the insulation is high.

The body has high insulation and corrosion resistance, and its service life is the same as that of the cable.

It is suitable for branch connection of copper/aluminum wires, different diameter wires, butt joints of equal-diameter wires, and transition connection of copper/aluminum insulated wires.

Easy install, low cost, safety, reliability and maintenance-free

» Read Less

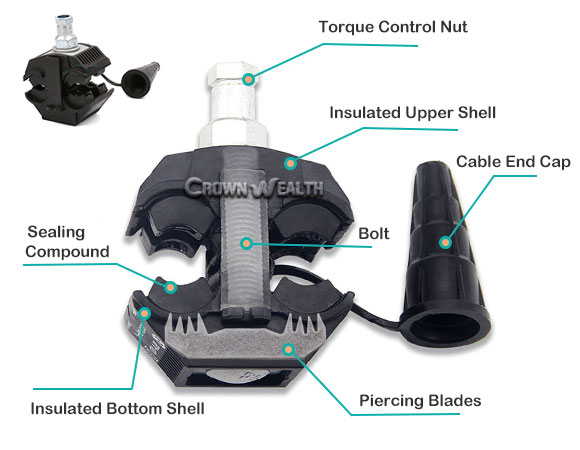

Piercing Blade: The piercing blade establishes the connection with the main line by piercing the insulation and connecting with the conductor in the cable.

Insulation Material: IPC cable connectors are designed with insulation housing made of UV-resistant rubber or plastic to enclose the piercing blade.

Sealing Components: To protect the IPC cable connector against damage caused by environmental wear such as corrosion and oxidation, sealing components are used to seal the connection point.

Clamping Mechanism: Include screws, bolts or other fasteners.

Note: Hbcrownwealth The IPC electrical connectors provided are all standard products, only the size is different, and the structure is basically the same.

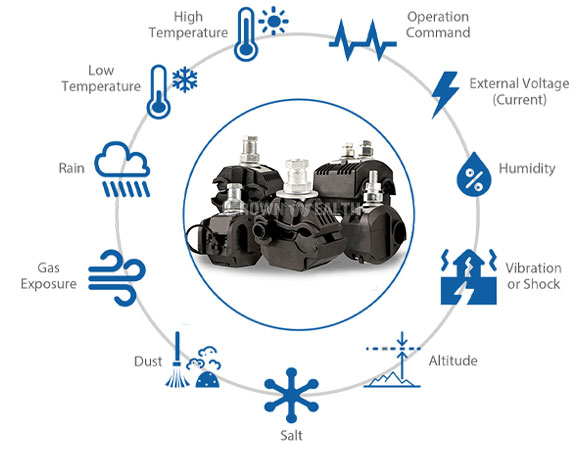

Designed for installation temperature range from –20 °C to +50 °C

Operational temperature range: -60°C to +60°C

Unrestricted mechanical load on main and branch conductors

Shear head force adapted to the required contact force for each application (main, service, lightning)

Withstands 6 KV in a 30 cm water bath

No change in contact resistance and temperature after overload and load cycling

Withstands 6 KV for metal balls after exposure to severe weather (UV, humidity and temperature cycling)

Good corrosion resistance of metal parts in salt spray chambers and humid SO₂ gas chambers

Overhead low voltage insulated cable connection and T-type connection

Building power distribution system cable connection

Street light distribution system and public cable field branch

Underground power grid insulated cable connection

Suitable for branch connection of insulated cable in 1KV distribution system

| Part NO. | Main Line Section | Branch Cross Section | Nominal Current | Overall Dimension | Puncture Depth | Material | |

|---|---|---|---|---|---|---|---|

| Body | Tooth Blade | ||||||

| CW-IPC 1-35 | 1.5-35mm² | 1.5-10mm² | 55A | 24×41×52mm | 1.5-2mm | Nylon | Copper, Red Copper, Aluminum |

| CW-IPC 1-95 | 16-95mm² | 1.5-10mm² | 55A | 24×41×52mm | 1-2mm | ||

| CW-IPC 2-95 | 16-95mm² | 4-35(50)mm² | 157A | 46×52×75mm | 1.5-2mm | ||

| CW-IPC 2-150 | 50-150mm² | 4-35(50)mm² | 157A | 45×52×75mm | 1.5-2.5mm | ||

| CW-IPC 3-95 | 25-95mm² | 25-95mm² | 214A | 50×61×100mm | 1.5-2mm | ||

| CW-IPC 3-120 | 16-120mm² | 16-120mm² | 214A | 50×61×100mm | 1.5-2mm | ||

| CW-IPC 3-150 | (35)50-150mm² | (35)50-150mm² | 316A | 50×61×100mm | 1.5-2.5mm | ||

| CW-IPC 4-240 | 120-240mm² | 25-120mm² | 211A | 52×68×100mm | 1.5-2.5mm | ||

| CW-IPC 5-240 | 150-240mm² | 10-25mm² | 102A | 52×68×100mm | 1.5-2.5mm | ||

Insulation piercing connector is a ABC cable connection product that replaces junction box and T-type junction box. It is not necessary to cut the main cable during construction, and the cable can be branched at any position. The wires and wire clamps do not need special treatment, and the operation is simple and fast. Compared with the traditional wiring method, it eliminates the processes of stripping insulation, tinning, crimping terminals, and insulation wrapping, reduces the inevitable environmental pollution of traditional methods, saves labor and installation costs, and is therefore widely used.

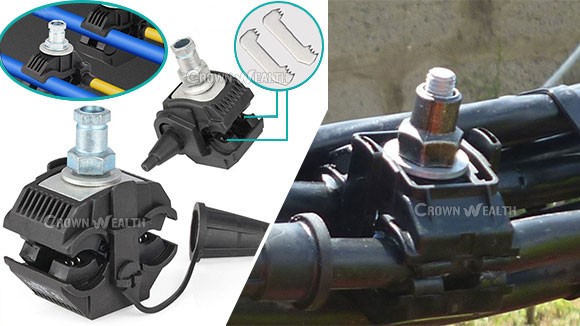

1. Adjust the connector nut to the appropriate position.

2. Put the branch cable into the cap completely.

3.Insert the main wire.If there are two lays of insulated in the main cable, strip a certain length of the first insulated lay from the inserted end.

4. Rotate the nut by hand to fix the connector in the appropriate position.

5.Screw the nut with the sleeve spanner.

6.Screw the nut continually until the top part is cracked and dropped down.

No.95 Qilian St. Shijiazhuang,China

info@hbcrownwealth.com

Phone: +86-311-89871588