Table of Contents

ToggleWhat is an Overhead Transmission Line?

An overhead transmission line is a crucial element in the electrical grid system. These lines carry high-voltage electrical power over long distances from power stations to substations, ultimately distributing electricity to consumers. Overhead transmission lines are the most common method of transmitting large amounts of electricity due to their ability to cover vast distances efficiently.

The setup consists of conductors, insulators, support structures, and various overhead line hardware. The design and components of these lines ensure that electricity reaches its destination without significant losses while minimizing the risk of system failure.

Understanding the components of an overhead transmission line is essential for suppliers, distributors, contractors, and engineers who are involved in electrical infrastructure projects.

Components of Overhead Transmission Line

The overhead transmission line is made up of several components, each serving a vital role in ensuring efficient and safe electricity transmission. Let’s take a closer look at these key components:

#1. Line Supports (Poles and Towers)

The pole line supports are the structures that hold the transmission lines in place. Common types of utility poles are generally made from steel, concrete, or wood and are designed to elevate the conductors to the required height and maintain clearance for safe operation.

– Steel Poles/Towers: Our focus is on hot-dip galvanized steel utility poles, known for their superior strength, corrosion resistance, and longer lifespan compared to other materials. These are commonly used for high-voltage lines due to ability to withstand harsh weather conditions.

– Concrete Poles: Used in areas with high corrosion or environmental exposure.

– Wooden Poles: Typically used for lower voltage transmission and in rural or less populated areas.

Hbcrownwealth Our steel utility poles are forged from high-quality carbon steel. The surface is evenly galvanized and is not easy to rust. The average service life can be more than 60 years.

#2. Insulators

Insulators are used to separate and support the conductors while preventing them from coming into contact with the support structures. These are crucial for maintaining the safety of the system and preventing electrical shorts.

– Porcelain: Traditionally used due to its durability and high electrical resistance.

– Toughened Glass: For insulation and suspension of conductors in high voltage and ultra-high voltage AC and DC transmission lines.

– Composite Materials: More modern materials that are lightweight and resistant to environmental degradation.

Based on the installation method, power line insulators can be roughly divided into two categories: Pin Insulators (installed on the line) and Suspension Insulators (installed under the line).

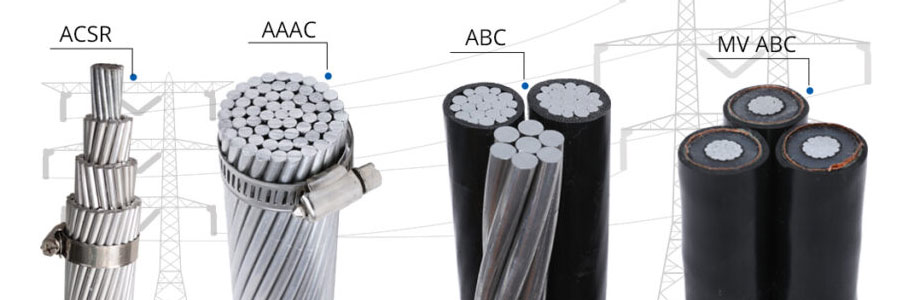

#3. Power Line Conductors

Overhead line conductors mainly carry transmission current. They are typically made from aluminum, copper, or aluminum-steel composites (ACSR), with the latter being the most common due to its strength and conductivity.

– ACSR (Aluminum Conductor Steel Reinforced): Often used for long-distance transmission because of its strength-to-weight ratio.

– Copper: Used for specific high-performance applications, although less common due to higher costs.

– Aluminum: Known for its light weight and good conductivity, ideal for various power lines.

#4. Grounding Systems and Earth Anchors

The grounding system ensures that any excess electrical charge, such as during a lightning strike or fault condition, is safely directed into the earth. Earth anchors are used to stabilize the transmission line poles and towers, ensuring their structural integrity under varying loads.

– Ground Conductors: Typically copper or aluminum wires used to connect the system to the ground.

– Earth Anchors: Also as No-Wrench acrew anchor, ensure the stability of the pole structure against forces like wind or ground movement.

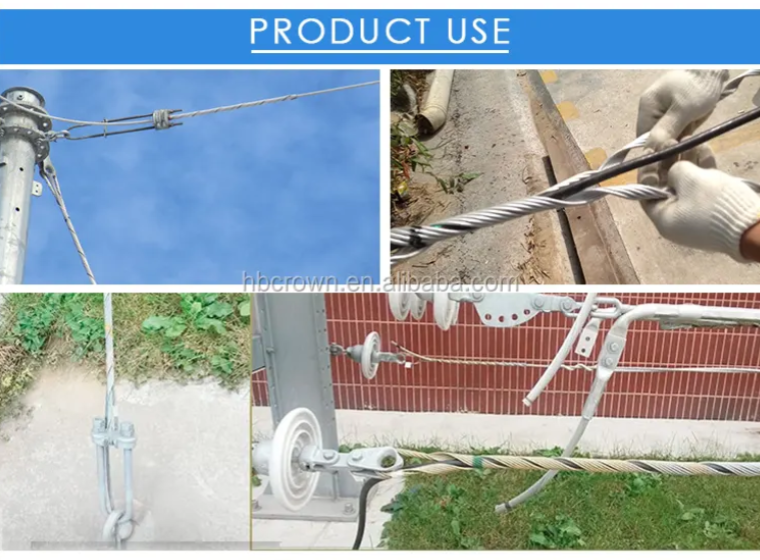

#5. Overhead Line Hardware and Fittings

Overhead transmission lines require a range of line hardware to ensure they operate safely and efficiently. These components are designed to handle high tension, secure conductors, and prevent mechanical failure. Here are some of the most commonly used overhead line hardware:

– Pole Band: This is hardware accessories used to fix on poles. Hbcrownwealth has a variety of pole band with different appearances and structural designs for you to choose from.

– Cross Arm: The electrical cross arms a pole mounted horizontally on a utility pole to support insulators and other pole line hardware. Provide support for conductors and maintain their distance from each other.

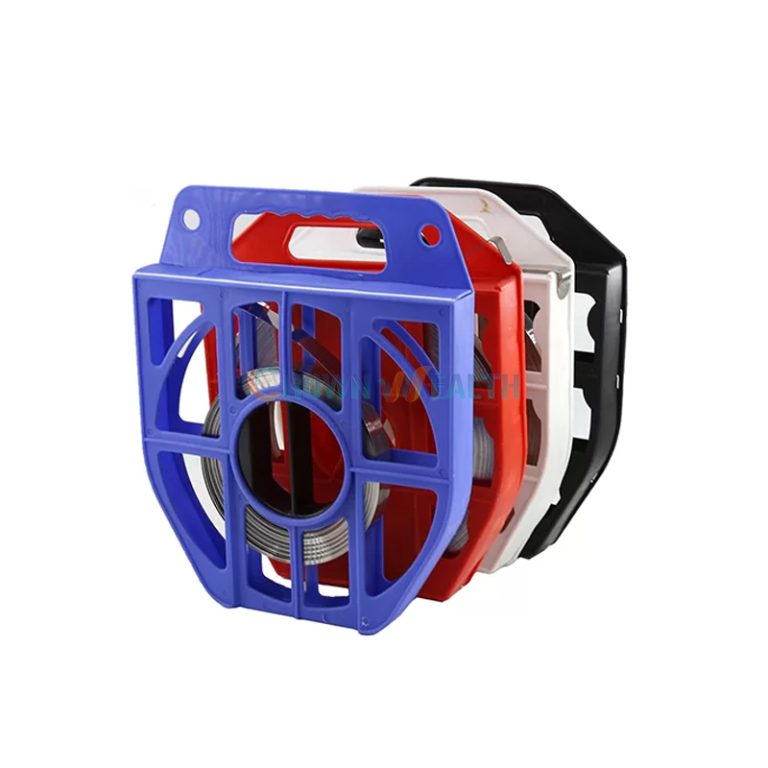

– Guy Wire: A strong steel cable used to reinforce the structure of a utility pole. Secure it firmly to the earth anchors with a guy wire clamp.

– Insulator Fittings: Secure insulators to the pole or tower.

– Vibration Dampers: Reduce the mechanical stress caused by wind and prevent line breakage.

– Lightning Arrester: A safety device that diverts lightning from a live line to the ground.

– Cable Clamps and Connectors: Used for securing and joining conductors cable, such as lashing wire clamp, span clamp, insulated piercing connector, etc.

– Tension & Suspension Clamp: Keeps the line under the correct tension and allows it to move freely during temperature changes, including anchoring clamp, guy grips, J suspension clamp and other types of preformed ADSS tension clamp and suspension clamp.

What Materials are Commonly Used in Components of Overhead Transmission Lines?

The materials used in overhead transmission lines are selected for their durability, strength, and ability to withstand the environmental stresses they face. Here are the most common materials:

– Aluminum: Widely used in conductors for its excellent conductivity and light weight.

– Copper: Known for superior conductivity, copper is used in specialized transmission lines.

– Steel: Often used in towers, anchors, and reinforced conductors due to its high tensile strength.

– Porcelain and Glass: Traditionally used in insulators for their ability to resist electrical breakdown and mechanical stress.

– Composite Materials: Used in modern insulators for their resistance to weathering and high performance under various electrical stresses.

The choice of materials for each component of the transmission line depends on factors like environmental conditions, voltage level, and budget. Ensuring that the right materials are used in the right applications is essential for the longevity and safety of the system.

Conclusion

For anyone involved in the planning, construction or maintenance of power infrastructure, it is important to understand the components of overhead transmission lines. From conductors to insulators and line hardware, they all play an important role in ensuring the safe and reliable transmission of power.

At Hbcrownwealth, as a reliable transmission line hardware manufacturer in China, we provide you with high-quality overhead power transmission line components that meet international standards and withstand the rigors of harsh environments.

If you are looking for overhead transmission line hardware, contact us today for expert advice and product recommendations for your specific needs.

FAQ

Types of Overhead Transmission Lines

By Voltage: Low Voltage (≤1kV); Medium Voltage; (1-100kV); High Voltage (100kV–765kV); Ultra-high Voltage (≥765kV);

By TransmissionDistance: Short Distance Line (≤80 km); Medium Distance Line (80-160 km); Long Distance Line (≥160 km);

By Circuit Type: Single Circuit; Double Circuit; Triple Circuit;

What are The Main Components Of An Overhead Transmission Line?

A: The main components include power line conductors, insulators, transmission poles, guy wires, and anchors.

What Role Do Insulators Play in an Overhead Transmission Line?

A: Insulators prevent the current from leaking to the ground, ensuring that electricity is transmitted safely and without loss through the line.

How are Transmission Line Conductors Selected?

A: Conductors are selected based on their material (typically aluminum or copper), voltage rating, and ability to handle the electrical load.

What is the Function Of a Transmission Pole in an Overhead Line?

A: Transmission poles support the conductors, keeping them elevated and separated to ensure safe transmission of electricity.

Why are Guy Wires Important for Overhead Transmission Lines?

A: Guy wires are used to stabilize transmission poles and prevent them from falling under the weight of the lines or during strong winds.

What are the Different Types Of Overhead Transmission Line Towers?

A: There are various types, including monopole, lattice, and guyed towers, each designed for different applications and environmental conditions.

What are Transmission Line Anchors and Why are They Necessary?

A: Anchors are used to secure guy wires and poles to the ground, ensuring the structural stability of the transmission line system.

How Does the Voltage Rating of an Overhead Transmission Line Affect Its Components?

A: Higher voltage lines require more robust components like stronger insulators and conductors that can handle greater electrical loads.

How Do Environmental Conditions Affect the Components of an Overhead Transmission Line?

A: Environmental factors like wind, temperature, and humidity can impact the durability and performance of components, which is why they are designed to withstand specific weather conditions.

.jpg)