Stainless steel cable ties are essential tools for you when it comes to bundling, securing, and managing cables, wires, and other items. Hebei Crown Wealth provides stainless steel cable ties made from high-quality 201/304/316 stainless steel materials. Some stainless steel cable ties also come with an epoxy coating or PVC coating, which can meet your needs for high tensile strength and corrosion-resistant cable ties. This article will introduce how to use and tighten stainless steel cable ties.

Table of Contents

ToggleStainless Steel Cable Ties Installation Process

Step 1: Prepare Materials

Choose stainless steel cable ties (metal tie size and type), stainless steel cable ties tool, and wear gloves suitable for your project application. If securing cables or objects, neatly comb them before using stainless steel cable ties to achieve a tidy and efficient fastening process.

Step 2: Position Stainless Steel Cable Ties

Wrap the stainless steel cable ties around the wires or objects you need to secure, placing it in the correct position. Ensure the cable ties completely surround the item to be secured, then thread the free end of the stainless steel cable ties through the locking device (the small opening or buckle at the cable ties head).

Step 3: Initial Manual Tensioning

Pull the free end (tail) of the stainless steel cable ties manually to secure it around your application. Ensure the secure cable ties remain balanced, applying even and steady tension, as adjusting the cable ties after full tightening can be difficult. Then check that the cable ties are tightened to prevent it from slipping off the fixed wires or objects.

Step 4: Use Tensioning Tool to Tighten Stainless Steel Cable Ties

If using a tensioning tool, follow the tool’s instructions to operate it and insert the free end of the stainless steel cable ties into the slot specified by the tool. Common tensioning tools use a crimping handle or ratchet to apply tension to the stainless steel cable ties. After using the tool, monitor the cables, wires, or other objects you’re securing to avoid excessive force that could unnecessarily damage or deform your application, ultimately affecting its effectiveness.

Step 5: Check for Secure Fastening

Inspect the tightness and stability of the stainless steel cable ties. Ensure it securely holds the item and that there are no loose connections. If adjustments are needed, be careful not to overtighten, as this could damage the stainless steel cable ties or the secured item.

Step 6: Secure and Cut Excess Length

Once the stainless steel cable ties effectively secures your object, use a tensioning tool (provided by Hebei Crown Wealth) to cut off the excess length. For a neat appearance of your application, cut as close to the locking device as possible while ensuring a secure hold.

*Friendly reminder: If uneven force or an old cutting tool prevents you from cutting the metal cable ties in one go, avoid unnecessary injury from its sharp edges by smoothing them with a file or high-strength sandpaper. Dispose of trimmed stainless steel cable ties in a designated recycling container due to potential risks associated with discarded cable ties.

How to Use Stainless Steel Cable Ties & How Do Work

The particularly outstanding benefits of stainless steel are its high strength, corrosion resistance, durability and low long-term use cost. You can watch the video of how to use stainless steel cable ties below:

Tips for Effective Use of Stainless Steel Cable Ties

· Choose the appropriate type of stainless steel cable ties based on your project’s specific application. Different environments may require stainless steel cable ties of varying strength, size, and performance. For general-purpose use, standard stainless steel cable tie is suitable for most bundling and fastening needs. However, in environments exposed to extreme temperatures or aggressive chemicals, consider coated stainless steel cable ties, for example, PVC coated stainless steel cable ties, nylon coated stainless steel cable ties and stainless steel cable ties coated with epoxy resin from Hebei Crown Wealth for high temperature resistance and weather durability. For securing fragile wires or cables, our stainless steel cable ties with rubber sleeve ensure the wires remain undamaged.

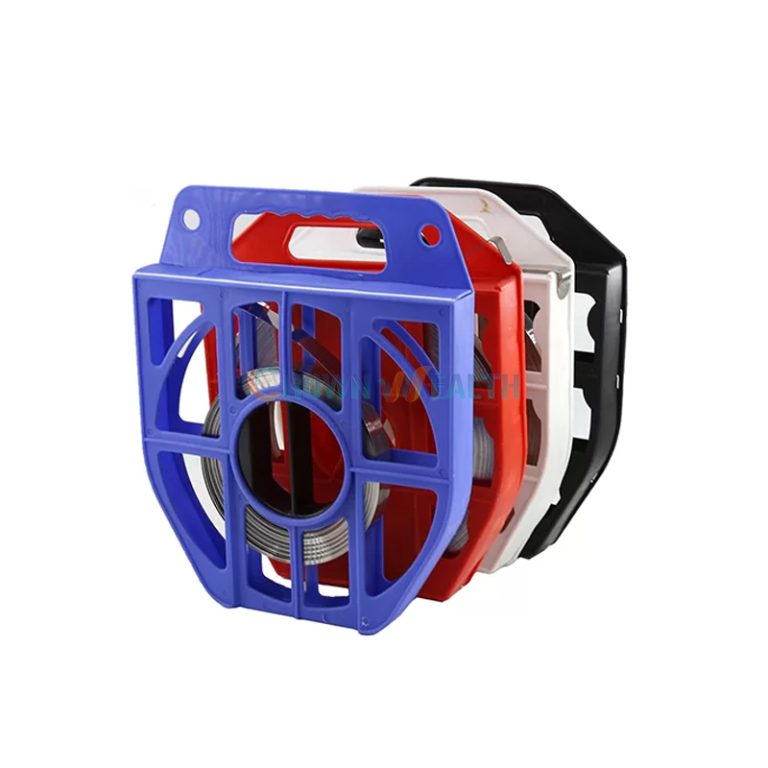

· Selecting the right tensioning tools is crucial, especially for larger or critical installations. Hebei Crown Wealth’s tensioning tools are rigorously tested for precision and durability through stringent quality control measures. Investing in our tensioning tools not only enhances project efficiency but also speeds up installation processes and ensures aesthetic outcomes, minimizing potential risks in your project application.

· Over time, regularly inspect stainless steel cable ties for signs of corrosion, wear, or loosening. Promptly identifying and replacing worn or damaged bands prevents costly repairs or unknown safety hazards that may arise from unchecked cable ties. Implementing routine inspections effectively safeguards the stable and safe operation of stainless steel cable ties in your applications.

Conclusion

In summary, using stainless steel cable ties allows you to effectively apply and tighten it, providing a stable, secure, and durable solution for your applications. Whether you’re working in an industrial setting or organizing cables at home, these cable ties offer a reliable method to securely fasten objects in place. For more information about stainless steel cable ties and tensioning tools, feel free to contact us anytime.

FAQ

What is a Stainless Steel Cable Tie?

Stainless steel cable ties, also as metal cable zip ties, are durable fastening devices used to secure cables, wires, and other objects.These cable ties typically feature a self-locking mechanism to ensure secure and stable operation in your applications.

Are Stainless Steel Cable Ties Made of?

Unlike nylon ties, stainless steel cable ties are made from high-strength, high-quality 201/304/316 stainless steel materials, offering excellent weather resistance, UV resistance, and corrosion resistance.

When to Use Stainless Steel Cable Ties?

You should consider using stainless steel cable ties for your application in the following environments or requirements:

- High-temperature, high-corrosive environments

- Fire-resistant needs

- Heavy-duty applications

- Electrical and cable management

- Construction and infrastructure

Are the Common Types of Stainless Steel Cable Ties?

- Self-locking stainless steel cable ties

- Ball-lock stainless steel cable ties

- Coated stainless steel cable ties

- Heavy duty stainless steel cable ties

- Adjustable stainless steel cable ties

- Trapezoidal multi-lock stainless steel cable ties

- Woolf teeth type buckles ties

What are the Applications Industry of Stainless Steel Cable Ties?

- Electrical and electronic equipment for cable and wire organization

- Bundling pipes and conduits

- Marine and shipboard applications

- Automotive and transportation

- Food processing and sanitary facilities

Stainless steel cable ties find extensive use across industrial and commercial facilities that require long-term durability and corrosion resistance.

.jpg)