We immerse ourselves in the joys of the internet every day, yet few people pay attention to the infrastructure that allows us to use the internet seamlessly. Statistics show that there are millions of signal towers, communication poles, and other utility pole types. What provides stability and support to these communication poles or tower and overhead Lines structures? The answer is clear: guy wires. So, what is a guy wire? Why is it called a guy wire? And how are guy wires installed and used? Follow the content of this guide, and let’s uncover this mystery together.

Table of Contents

ToggleWhat is a Guy Wire? Definition of Guy Wire

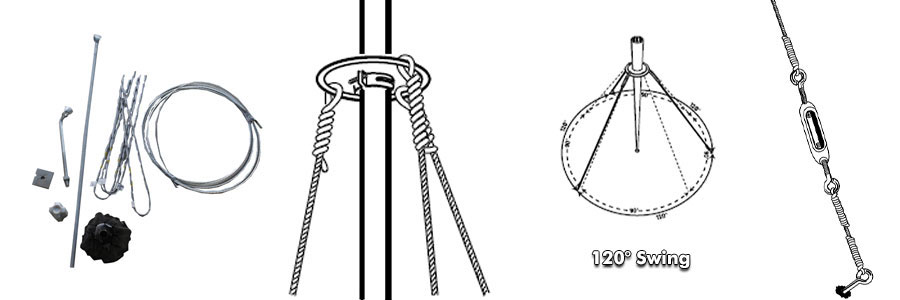

Guy wire is a rope used to stabilize, guide or fix something. It is guy cables that carry tension and help in the safety and stability of structures such as telecommunication poles or towers. One end of the guy wire is anchored to the concrete in ground, while the other end is secured at various heights along the structure it supports, such as a telecom pole or tower. Antenna masts are typically supported by three guy wires at 120° angles. Structures with predictable lateral loads, such as utility poles, may require only one guy wire to counteract the lateral pull of the wire where it changes direction. Guy wires can be used in conjunction with various electrical hardware and accessories, making them highly versatile in their applications.

Why is It Called Guy Wire? Guy Wire or Guide Wire

Have you ever wondered why it’s called guy wire? Guy wire has a long history, starting with the French coining the word “guie” about 800 years ago, and ending in the early 1600s when the Dutch began using “gei” (“guy”) as the name for the rope or wire used to secure a mast or mainsail on their ships. Today, hundreds of years later, the word “guy” has been retained as the name for any tensioned guy cable used to stabilize ship masts, transmission towers, wind turbines, and guy wire utility poles. Guy wire can also be called guyed wire, guy cable, guy strand, and guy anchors (guy wire anchor), sometimes mistakenly called “guide wire”.

What is a Guy Wire Made of?

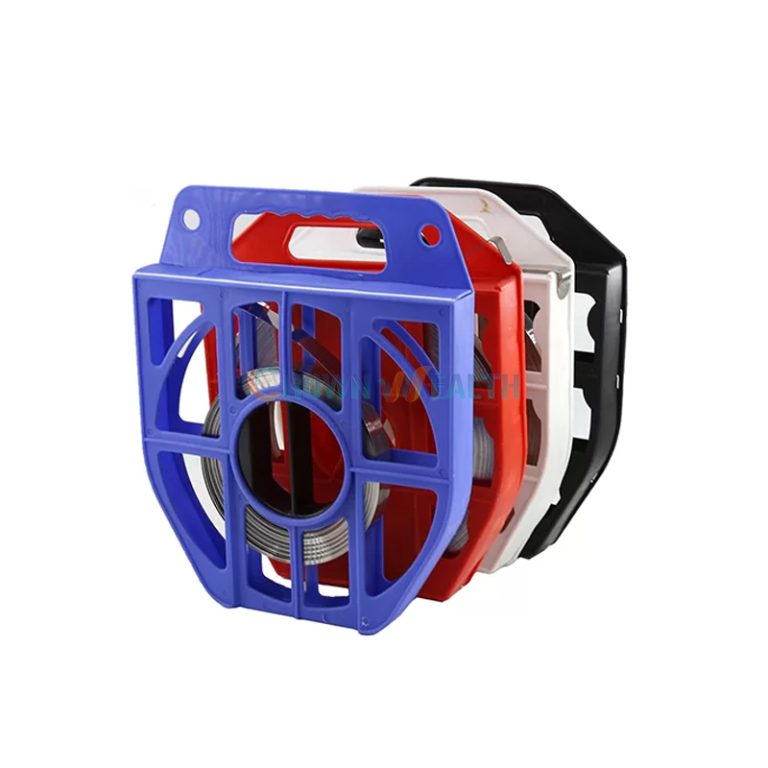

The guy wire is a tensioned cable and is a supporting component that ensures the safety and stability of the tower structure. Hebei Crown Wealth Guy wire is made of galvanized steel, stainless steel or steel coated with composite materials. Ultra-high strength steel meets ASTM A475 standards. Guy wire is widely used in outdoor applications, including utility poles, communication towers, antenna poles or ships. These materials can prevent rust and corrosion due to long-term exposure to humid environments. Especially on ships, which are exposed to highly corrosive marine environments for a long time, the material of the guy wire is important to maintain its original durability.

Types of Guy Wires

Galvanized Steel Guy Wire

Galvanized Steel Guy Wire is made of high-strength galvanized steel wire with a premium anti-corrosion coating consisting of 5% aluminum and 95% zinc to properly support your tower or mast. All of Hebei Crown Wealth’s galvanized steel wire is free of scale, unevenness, overflow, cracks or other defects. Each wire is fully and smoothly galvanized before stranding. Base metal is steel made by open-hearth steelmaking, basic oxygen steelmaking or electric furnace steelmaking processes. It is widely used due to its strength and durability.

Stainless Steel Guy Wires

Stainless Steel Guy Wires are made of high-quality 201/304/304 stainless steel, which has excellent rust resistance and can resist corrosion from most oxidizing acids. 316 stainless steel is a marine grade stainless steel, 316 stainless steel guy wires that can maintain its original properties in a high-salt marine environment. Hebei Crown Wealth produces stainless steel guy wires suitable for rigging, lifting, towing and heavy construction applications, including shade structures, sails, wire railings, building rigging and cable trellises.

How is a Guy Wire Used?

You see guy wires every day in your daily life, even if you don’t realize it. Guy wires are often found on overhead transmission line poles or telecom poles in power systems to secure poles or towers. One end of the guy wire is connected to a force distribution point high up in the tower structure, and the other end is anchored to a safety anchor bolt in the concrete floor. Multiple guy wires are angled to ensure the stability of the structure. Anchor bolts in the concrete floor can be used to secure one or more guy wires. Whether you are using it temporarily or permanently, guy wires can protect towers or buildings from tilting or collapsing when subjected to strong wind loads, thereby enhancing the safety of the surrounding area.

Different Application of a Guy Wire

The guy wires provided by Hebei Crown Wealth can be used in power system transmission lines, telecommunications & broadcasting towers, ship masts and steel structures. The following is a brief description of the wide range of uses of guy wires:

Guy Wires for Power System

Guy wires are commonly used in power systems and are generally applications to support utility poles or towers, including structures such as telephone lines, cables and power pole guy wire. Many utility lines have long transmission distances and require the establishment of many utility poles or towers, which are generally buried underground. Due to the huge tension in the span of the utility line pole or tower, guy wires are required between the pole and the ground to support the unbalanced lateral loads, including the tension between the poles and the unstable wind load, to ensure that the utility poles are upright and not tilted.

Safety Tips: A guy wire is usually used with a guy insulator, which is insulated to avoid electric shock if any person touches it.

Guy Wires for Telecommunications and Broadcasting

In today’s society, whether you use communication wireless equipment or broadcasting and television, you can’t do without signal transmission. Signal towers carry the vital signal transmission carrier. The stability of the tower affects people using telecommunications and broadcasting in the surrounding area, so guy wires are used to increase the stability of the tower structure. The guy wires used to support telecommunications and broadcasting towers or antenna masts are roughly the same as the guy wires of power systems. In order to prevent the steel strands from adding interference signals to communications, the guy wires need to be insulated.

Guy Wires for Ships

Guy wires are used to support ship masts, making sailing safer and easier. Guy wires are made of stainless steel, which helps prevent rust, especially when in frequent contact with water in a marine environment.

Guy Wires for Flare Stacks

When faced with swaying forces imposed on the flare stack structure due to wind loads, the flare stack may experience vortex shedding. Although a flare stack is generally designed to stand on its own, the use of guy wires can enhance its stability in the face of wind loads and mitigate the effects of vortex shedding. When selecting supports for the flare stack, consider the additional ground space required to anchor the guy wires required for stability.

Guy Wires for Turbines

Although the turbine can stand upright on its own, due to the nature of its work to withstand the strong forces from wind loads, additional guy wire support can increase the turbine’s sturdiness and stability. The guy wire of the turbine usually needs to be half to three quarters of the height of the turbine, providing sufficient anchoring space.

How to Install a Guy Wire?

Prepare Materials: Prepare all the hardware accessories needed to install the guy wires.

Anchor Installation: Secure the anchor device to the ground, about two-thirds of the height of the tower structure.

Connect the Guy Wires: Connect the guy wires to the designated anchor bolts and tower structure connection points, making sure they are evenly distributed around the structure.

Tensioning: Use turnbuckles to adjust the tension of the guy wires. They should be taut, but not too tight to allow some flexibility.

Safety Inspection: Check all connections to ensure that the guy wires are not kinked or frayed. Check and maintain tension regularly.

Guy Wire Hardware Fittings

Dead-end Guy Grips

For use with guy wires on pole or tower structures for overhead line transmission such as communications, antennas, power lines, etc., dead-end guy grips need to be constructed, generally these preformed tension clamp. They are used to establish a termination point at the end of the guy wire.

Guy Grips

Each spiral of the guy grip has a gripping point made of crushed stone to firmly hold the load-bearing conductor or fiber optic cable. Also known as preformed guy grips, it is used to connect and clamp ground wires, conductors and fiber optic systems.

Cable Suspension Clamp

Cable Suspension Clamp is also called Guy Clamp (or guy wire clamp). Common types include two-eye bolts, three-eye bolts and serpentine suspension clamps. Guy clamps are used on communication pole lines to stabilize the rods together with the cables and anchors. Parallel grooves hold the steel strands securely without causing damage. Each bolt has a shoulder to prevent rotation when tightening. Constructed of high quality steel, hot-dip galvanized.

Wire Rope Thimble

Wire Rope Thimble is also called Guy Thimble, widely used as wire rope accessories, chain accessories, hardware accessories clamps. In wire pulling applications, it is used to form oval wire eyes for fixing to eyebolts (such as thimble guy bolts rod, oval eye bolt) and guy wire rods. The surface treatment is hot-dip galvanizing, which has good corrosion resistance and strong durability. Different sizes are suitable for wires of different diameters and sizes, such as prefabricated wire clamps.

Pole Band

Common pole bands include single offset pole bands, double offset pole bands, adjustable pole bands, drop wire mast brackets, and link style pole bands. There are different pole bands for utility poles, and telephone poles. Pole band clamps can be used with guy wires. Cable pole bands are often used to connect ADSS and OPGW cables. The raw material of pole bands is flat carbon steel, not stripped steel, and is hot-dip galvanized. The pole bands will not break or crack after flat steel stamping.

Shackle

Hebei Crown Wealth provides various types of Shackle, including US Type Bow Shackle, US Type Dee Shackle, UL Type Galvanized Steel Wire Rope Clamp, Din741 Malleable Clip. Used to connect wire ropes, chains and slings.

Turnbuckle

The galvanized turnbuckle is used to pull together or push apart the guy anchor. It is also used to correct the tension or length of the rope.

Stay Rod

The stay rod is used at the connection between the guy wire and the electric pole in the tower structure to prevent the guy wire from collapsing due to stress.

Stay Insulator

The stay insulators used for guy wires are at high voltage so that the tension on the cable is converted into force. Using guy wire insulators helps prevent current from flowing where it is not wanted.

How to Select Guy Wire?

Choosing the right guy wire for your project application is crucial to ensuring the stability and safety of the tower structure. Here are some factors to consider when choosing a guy wire:

- Material: Common material types include galvanized steel, stainless steel, and synthetic materials. Galvanized steel and stainless steel have excellent corrosion resistance and can be used in marine environment facilities. Synthetic materials are lightweight and non-conductive.

- Application Scenarios: Galvanized steel guy wires are preferred for utility poles, communication towers, and antenna pole facilities. 316 stainless steel guy wires are your ideal solution for high-salt, high-corrosion marine or chemical and pharmaceutical environments.

- Length and Diameter: According to the application environment of your project, scientifically judge the force of the tower structure subjected to external loads and select guy wires with corresponding bearing capacity. Generally, the length of the guy wire is determined according to the height of the tower (the guy wire is fixed at two-thirds of the tower structure).

- Compliance with Standards: Choose a professional guy wire supplier, and judge whether it meets the industry’s specifications and some performance certifications based on the guy wire specifications provided by the guy wire supplier.

- Cost and Availability: Of course, while considering the above factors, you must also consider the procurement cost of your project application. A guy wire with high cost performance while ensuring guy wire performance is your best choice.

How to Choose the Guy Wire Manufacturer & Suppliers?

A professional and high-quality supplier with high technology and production capacity allows you to reduce your investment in cable and related hardware products. Here are some factors to consider when choosing a supplier or manufacturer:

– Check whether the company is legal and has obtained a business license

– Company size and production capacity

– Whether the production meets the quality standards of your project application area

– Whether samples can be sent for quality testing

– Check the comprehensive reviews of the manufacturer’s related operating platforms

If you want to find a supplier in China, Hebei Crown Wealth, as a professional and reliable cable manufacturer and supplier in China, can provide you with a range of cable and its hardware accessories products. It can also provide you with customized size services and provide you with the most competitive ex-factory prices in the market. If you have any questions about cable, please feel free to contact us.

Conclusion

Guy wires were originally used to provide support for ship masts to aid navigation. They can be found in power systems, telecommunications, and broadcasting. Guy wires are installed diagonally away from the pole or tower, helping to spread out the unbalanced load in the overhead line. Guy wires are mainly used to support the height of tall poles or overhead structures to increase stability and prevent the pole from collapsing, bending or breaking. Guy wires also provide security by shielding the structure from strong winds or storms that may affect the structure. If you have any questions about guy wires, feel free to contact us.

FAQ

How to Inspections and Tests on Guy Wires?

– Regularly check the connection points between the guy wire and the pole tower and anchor bolts. Due to the influence of external loads, there may be signs of rust or corrosion.

– Regularly check the use of guy wire hardware accessories

– Check whether the guy wire is corroded, kinked or broken

– Use non-destructive mechanical testing to detect the tension of the guy wire. The tension of the guy wire should not be too loose or too tight

– The guy wire should be tested at least once every natural year. In high-salt and high-corrosion environments, the number of tests should be increased within a natural year.

Features of Guy Wires

- Made of high-quality raw materials

- Minimal damage to the surface when slightly stretched, can protect the structure for a long time

- Can withstand huge tension even with high breaking strength of broken wires

- Maintains its durability and service life with low maintenance

- Quickly and safely add hardware

Factors That Affect Guy Wire Specifications

- The strength of the guy wire depends on whether the guy wire material can withstand a greater load

- The guy wire length should ensure the best tension from the tower to the ground

- The guy wire size meets the guy wire strength requirements

- Whether the anti-corrosion protection galvanized coating is uniform and the coating thickness is guaranteed to reduce the corrosion and rust of the guy wire

- The elasticity and hardness of the guy wire are balanced as much as possible to ensure sufficient protection to resist the twisting force, thereby preventing the guy wire from breaking or structural damage and maintaining the stability of the supporting structure

What is the Types of Guy Wire Stranding?

Guy wire strands can be either 1*7 or 1*19. They are called 7-wire and 19-wire, respectively.

.jpg)