Electric Pole Accessories

- Home

- Products

- Hot Products, Stainless Steel Banding Strap, Stainless Steel Banding Strap

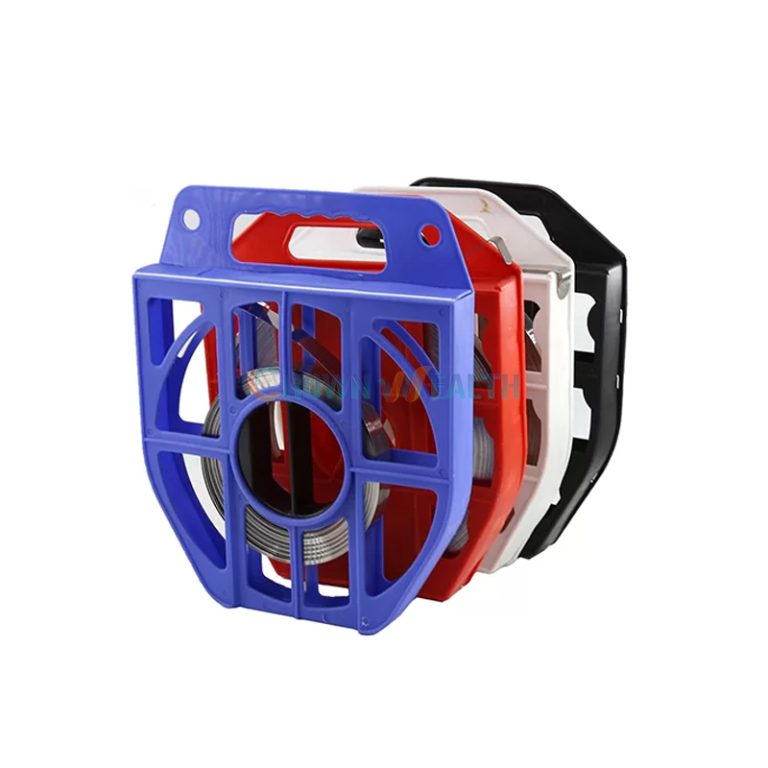

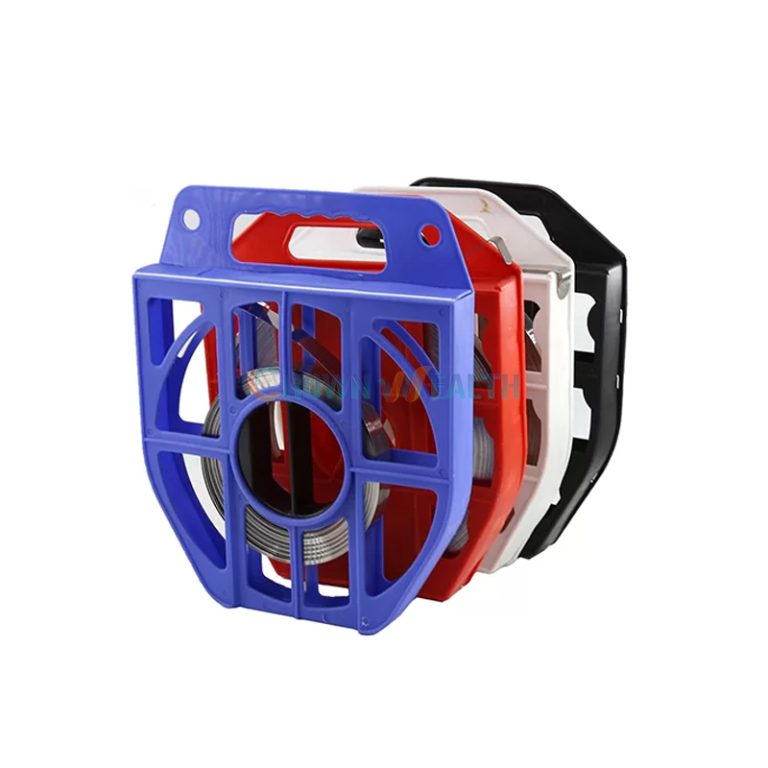

- CW-SPB: Banding Strap in Plastic Dispenser Box

We are offers a full range of stainless steel banding or strapping with a clean appearance, oxidation and weather resistance, including 1/4″ to 3/4″ to cover most of your stainless steel band needs.

We are offers a full range of stainless steel banding or strapping with a clean appearance, oxidation and weather resistance, including 1/4″ to 3/4″ to cover most of your stainless steel band needs.

Description

Hebei Crown Wealth offers a full range of stainless steel banding or strapping with a clean appearance, oxidation and weather resistance, including 1/4″ to 3/4″ to cover most of your stainless steel band needs.

Can be used in almost any environment, providing very good corrosion resistance in fresh water and industrial environments. Typically chosen for light-duty applications in food processing, chemistry, power transmission and cable management.

Leading supplier of stainless steel straps, buckles, clips and compatible stainless steel banding tools. Other widths can be made to order with very short lead times.

Parameters

| Parts No. | Description | Material | Width/Inch | Thickness/mm |

| CW-SPB | Banding Strap in Plastic Dispenser Box | SS201/304/316 | 1/4″-3/4″ | 0.6/0.7/0.76 |

FAQ

Q: What is stainless steel banding straps?

A: Stainless steel banding are used to secure metal fittings over insulation, keeping them in place. The most common widths for stainless steel banding are ½” and ¾” with roll lengths and thickness for bands varying depending on your needs.

Q: What material is used for stainless steel banding straps?

A: Different environments have different requirements for the performance of stainless steel strips. The three most commonly used grades: SS 201, SS 304 and SS 316. Can be use in different environments,and appropriate stainless steel materials can do our job and help us save money.

Q: How to choose the material of stainless steel banding straps?

A: The stainless steel material determines the physical and chemical properties of the stainless steel straps.

– 201 stainless steel has high tensile strength, strong oxidation resistance and moderate corrosion resistance. 201 stainless steel strip can be applied to general outdoor environment. Rust-proof and corrosion-resistant, it can ensure that it can withstand the humidity and ultraviolet environment of the outdoor environment and is still stable.

– 304 stainless steel has strong corrosion resistance and high toughness. 304 stainless steel belt can be used in some environments that need to withstand chemical corrosion, such as chemical plants and paper mills. It can resist corrosion and maintain toughness. Even when it exceeds its tensile limit, the super toughness will not tear easily. It can be competent for environments with higher security requirements.

– 316 stainless steel enhances the ability to resist chloride ions on the basis of 304 stainless steel. 316 stainless steel belt can perfectly replace the use of 304 stainless steel, and can be competent in the environment of contact with seawater and saline environment. It has stronger resistance to intergranular corrosion, which can ensure that your work is foolproof.

Q: Could you introduce the production advantages for your straps?

A: Stainless steel banding straps with stainless steel in a shiny finish, offers good resistance to oxidation and many moderate corrosive agents when you use them

Q: How do you pack the stainless steel banding straps usually?

A: Common Packing: 100Pcs+Box+Label+ Carton, or according customers requirement.

Q: Are you trading company or manufacturer for the banding straps?

A: We are a factory, but we can guarantee that our quotation is first-hand, very cheap and competitive in your market.

Q: How could I get a sample?

A: The samples are free, you just bear the freight. Express delivery charge depends on the quantity of the samples.

Q: How to Install Stainless Steel Strapping?

| Parts No. | Description | Material | Width/Inch | Thickness/mm |

| CW-SPB | Banding Strap in Plastic Dispenser Box | SS201/304/316 | 1/4″-3/4″ | 0.6/0.7/0.76 |

Description

Hebei Crown Wealth offers a full range of stainless steel banding or strapping with a clean appearance, oxidation and weather resistance, including 1/4″ to 3/4″ to cover most of your stainless steel band needs.

Can be used in almost any environment, providing very good corrosion resistance in fresh water and industrial environments. Typically chosen for light-duty applications in food processing, chemistry, power transmission and cable management.

Leading supplier of stainless steel straps, buckles, clips and compatible stainless steel banding tools. Other widths can be made to order with very short lead times.

Parameters

| Parts No. | Description | Material | Width/Inch | Thickness/mm |

| CW-SPB | Banding Strap in Plastic Dispenser Box | SS201/304/316 | 1/4″-3/4″ | 0.6/0.7/0.76 |

FAQ

Q: What is stainless steel banding straps?

A: Stainless steel banding are used to secure metal fittings over insulation, keeping them in place. The most common widths for stainless steel banding are ½” and ¾” with roll lengths and thickness for bands varying depending on your needs.

Q: What material is used for stainless steel banding straps?

A: Different environments have different requirements for the performance of stainless steel strips. The three most commonly used grades: SS 201, SS 304 and SS 316. Can be use in different environments,and appropriate stainless steel materials can do our job and help us save money.

Q: How to choose the material of stainless steel banding straps?

A: The stainless steel material determines the physical and chemical properties of the stainless steel straps.

– 201 stainless steel has high tensile strength, strong oxidation resistance and moderate corrosion resistance. 201 stainless steel strip can be applied to general outdoor environment. Rust-proof and corrosion-resistant, it can ensure that it can withstand the humidity and ultraviolet environment of the outdoor environment and is still stable.

– 304 stainless steel has strong corrosion resistance and high toughness. 304 stainless steel belt can be used in some environments that need to withstand chemical corrosion, such as chemical plants and paper mills. It can resist corrosion and maintain toughness. Even when it exceeds its tensile limit, the super toughness will not tear easily. It can be competent for environments with higher security requirements.

– 316 stainless steel enhances the ability to resist chloride ions on the basis of 304 stainless steel. 316 stainless steel belt can perfectly replace the use of 304 stainless steel, and can be competent in the environment of contact with seawater and saline environment. It has stronger resistance to intergranular corrosion, which can ensure that your work is foolproof.

Q: Could you introduce the production advantages for your straps?

A: Stainless steel banding straps with stainless steel in a shiny finish, offers good resistance to oxidation and many moderate corrosive agents when you use them

Q: How do you pack the stainless steel banding straps usually?

A: Common Packing: 100Pcs+Box+Label+ Carton, or according customers requirement.

Q: Are you trading company or manufacturer for the banding straps?

A: We are a factory, but we can guarantee that our quotation is first-hand, very cheap and competitive in your market.

Q: How could I get a sample?

A: The samples are free, you just bear the freight. Express delivery charge depends on the quantity of the samples.

Q: How to Install Stainless Steel Strapping?

| Parts No. | Description | Material | Width/Inch | Thickness/mm |

| CW-SPB | Banding Strap in Plastic Dispenser Box | SS201/304/316 | 1/4″-3/4″ | 0.6/0.7/0.76 |

No.95 Qilian St. Shijiazhuang,China

info@hbcrownwealth.com

Phone: +86-311-89871588