Electric Pole Accessories

- Home

- Products

- Preformed Tension Clamp

- CW-SG: Service Grip Dead End

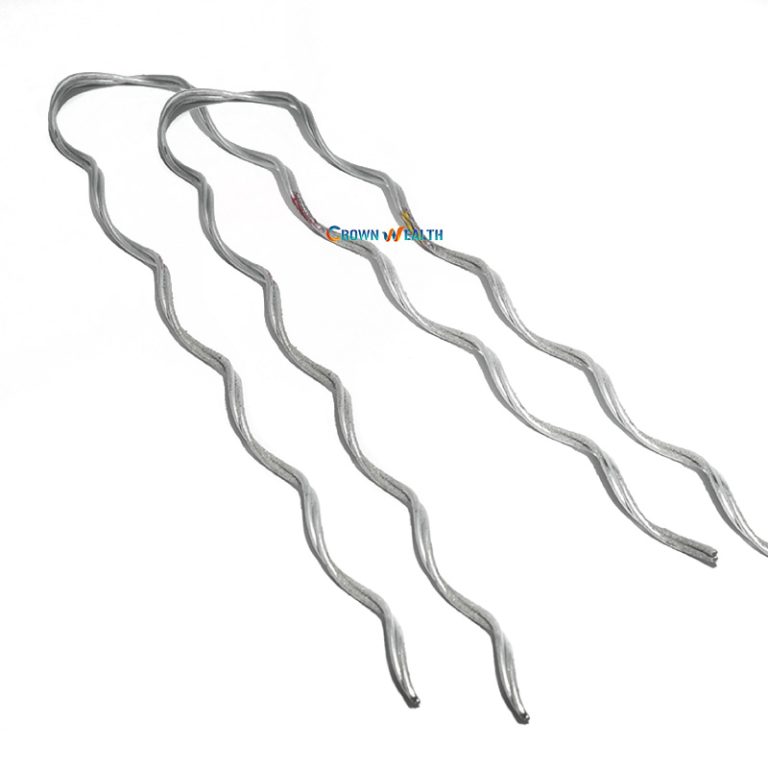

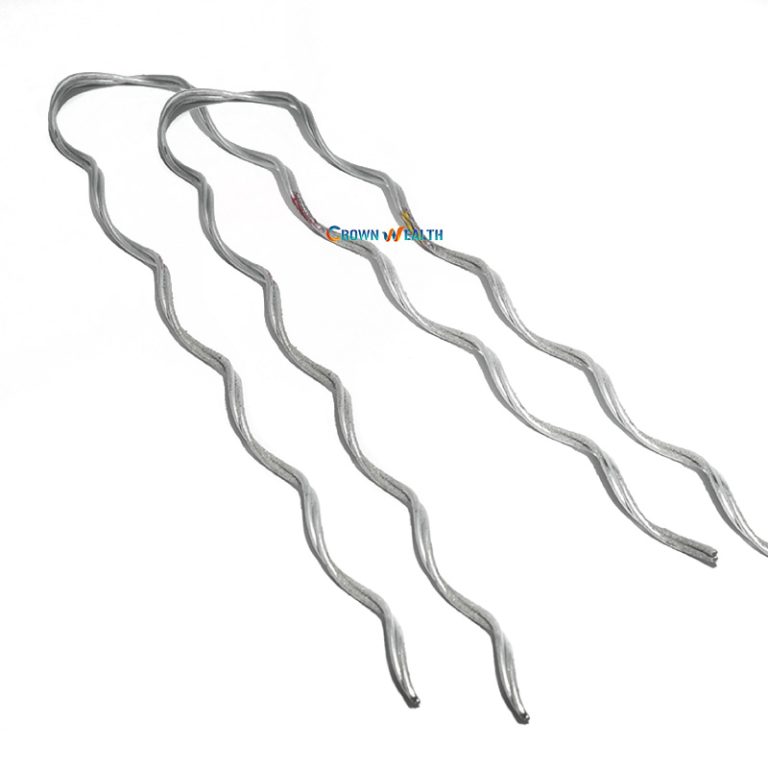

Service-Grip Dead-ends are used in transmission, communication, antenna and other wire-pulling structures that require the use of large guy wires. These are designed to develop the optimum load for a particular wire harness.

Service-Grip Dead-end are actually partial tension devices that are capable of withstanding at least 50% of the rated breaking strength of the specified conductor. They are used to hold the neutral messenger in place in service drop applications. They are compatible with different conductors including AAC, ACSR and AAAC.

Service-Grip Dead-ends are used in transmission, communication, antenna and other wire-pulling structures that require the use of large guy wires. These are designed to develop the optimum load for a particular wire harness.

Service-Grip Dead-end are actually partial tension devices that are capable of withstanding at least 50% of the rated breaking strength of the specified conductor. They are used to hold the neutral messenger in place in service drop applications. They are compatible with different conductors including AAC, ACSR and AAAC.

Description

Hbcrownwealth Service-Grip Dead-end manufactured of premium aluminum-covered steel, is designed for bare neutral messengers of self-supporting cable used in making service drops.

Mechanical strength meets the requirements for NESC Grade “N”, Rule 263-E, Supply Services, Spans not exceeding 150 feet.

That you use dead-end is recommended for service drops by reason of minimum length, economy, and neatness of appearance.

For service drops exceeding 150 feet, Grade “C” Construction, it’s recommended that you use Distribution-Grip Dead-end.

Rated Holding Strength: Hbcrownwealth In arriving at “Rated Holding Strengths”, actual results of tests on unweathered conductor are studied, and consideration is given to dimensional tolerances for the sizes encompassed. These minimum values are conservative when compared to “typical” values, or, actual tests on conductor which has been in service.

Tapping: Tapping over the applied legs of Service-Grip Dead-end is not recommended. Taps can be made on the conductor, ahead of the Dead-end, or, the conductor can continue through the crossover point of the grip with connectors applied to the continued tail.

Vibration Dampers: No consideration of dampening devices with Service-Grip Dead-ends is made since Distribution-Grip Dead-ends are recommended when vibration is suspected.

Crossover Marks: Indicate starting point for application.

Color Code and Length: Assist in identification of conductor size.

Identification Tape: Shows catalog number, nominal sizes.

For Use On: ACSR, All-Aluminum, Aluminum Alloy, Compacted ACSR Compacted All-Aluminum

Parameters

| Parts No. | Diameter Range | Length | Color Code | Max. Neck Dia. | |

| Min. | Max. | ||||

| CW-SG11 | .169″ | .198″ | 11″ | Blue | 2-3/8″ |

| CW-SG12 | .199″ | .224″ | 12″ | White | 2-3/8″ |

| CW-SG13 | .225″ | .257″ | 13″ | Orange | 2-3/8″ |

| CW-SG14 | .258″ | .289″ | 14″ | Black | 2-5/8″ |

| CW-SG15 | .290″ | .325″ | 15″ | Red | 2-5/8″ |

| CW-SG17 | .326″ | .360″ | 17″ | Green | 2-5/8″ |

| CW-SG19 | .361″ | .400″ | 19″ | Yellow | 2-7/8″ |

| CW-SG21 | .401″ | .450″ | 21″ | Blue | 2-7/8″ |

| CW-SG23 | .451″ | .510″ | 23″ | Orange | 2-7/8″ |

| CW-SG26 | .511″ | .580″ | 26″ | Red | 3″ |

Safety Use Precautions

1. When working in the area of energized lines with this product, EXTRA CARE should be taken to prevent accidental electrical contact.

2. For PROPER PERFORMANCE AND PERSONAL SAFETY be sure to select the proper size Service-Grip Dead-end before application.

3. The loops of Service-Grip Dead-ends should not be crisscrossed, when two or more are applied to the same spool.

4. This product is intended for a single (one-time) use and for the specified application, although it may be reapplied twice for retensioning within 90 days of initial installation.

Caution: Do not modify or reuse this product after 90 days under any circumstances.

Description

Hbcrownwealth Service-Grip Dead-end manufactured of premium aluminum-covered steel, is designed for bare neutral messengers of self-supporting cable used in making service drops.

Mechanical strength meets the requirements for NESC Grade “N”, Rule 263-E, Supply Services, Spans not exceeding 150 feet.

That you use dead-end is recommended for service drops by reason of minimum length, economy, and neatness of appearance.

For service drops exceeding 150 feet, Grade “C” Construction, it’s recommended that you use Distribution-Grip Dead-end.

Rated Holding Strength: Hbcrownwealth In arriving at “Rated Holding Strengths”, actual results of tests on unweathered conductor are studied, and consideration is given to dimensional tolerances for the sizes encompassed. These minimum values are conservative when compared to “typical” values, or, actual tests on conductor which has been in service.

Tapping: Tapping over the applied legs of Service-Grip Dead-end is not recommended. Taps can be made on the conductor, ahead of the Dead-end, or, the conductor can continue through the crossover point of the grip with connectors applied to the continued tail.

Vibration Dampers: No consideration of dampening devices with Service-Grip Dead-ends is made since Distribution-Grip Dead-ends are recommended when vibration is suspected.

Crossover Marks: Indicate starting point for application.

Color Code and Length: Assist in identification of conductor size.

Identification Tape: Shows catalog number, nominal sizes.

For Use On: ACSR, All-Aluminum, Aluminum Alloy, Compacted ACSR Compacted All-Aluminum

Parameters

| Parts No. | Diameter Range | Length | Color Code | Max. Neck Dia. | |

| Min. | Max. | ||||

| CW-SG11 | .169″ | .198″ | 11″ | Blue | 2-3/8″ |

| CW-SG12 | .199″ | .224″ | 12″ | White | 2-3/8″ |

| CW-SG13 | .225″ | .257″ | 13″ | Orange | 2-3/8″ |

| CW-SG14 | .258″ | .289″ | 14″ | Black | 2-5/8″ |

| CW-SG15 | .290″ | .325″ | 15″ | Red | 2-5/8″ |

| CW-SG17 | .326″ | .360″ | 17″ | Green | 2-5/8″ |

| CW-SG19 | .361″ | .400″ | 19″ | Yellow | 2-7/8″ |

| CW-SG21 | .401″ | .450″ | 21″ | Blue | 2-7/8″ |

| CW-SG23 | .451″ | .510″ | 23″ | Orange | 2-7/8″ |

| CW-SG26 | .511″ | .580″ | 26″ | Red | 3″ |

Safety Use Precautions

1. When working in the area of energized lines with this product, EXTRA CARE should be taken to prevent accidental electrical contact.

2. For PROPER PERFORMANCE AND PERSONAL SAFETY be sure to select the proper size Service-Grip Dead-end before application.

3. The loops of Service-Grip Dead-ends should not be crisscrossed, when two or more are applied to the same spool.

4. This product is intended for a single (one-time) use and for the specified application, although it may be reapplied twice for retensioning within 90 days of initial installation.

Caution: Do not modify or reuse this product after 90 days under any circumstances.

No.95 Qilian St. Shijiazhuang,China

info@hbcrownwealth.com

Phone: +86-311-89871588